Enterprise users are large companies that use services and technologies for business initiatives. Many enterprise users use digital twin technologies for different use cases within the digital twin space. This article will discuss these large corporations’ use of digital twin software, shedding light on how the market is segmented. The market can be segmented into digital twin software, hardware providers, and core companies providing these utilities. Enterprise users are companies that use the technologies provided by the providers.

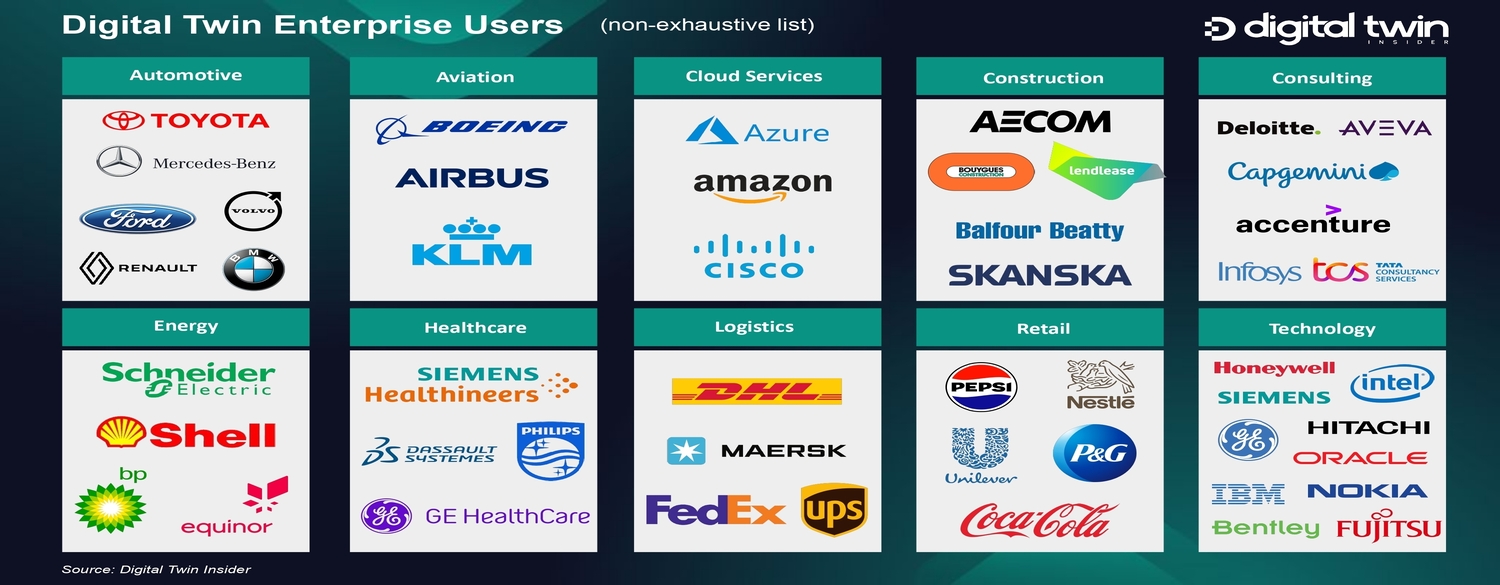

As we dive into the key enterprise users, we see an overlap between providers and users, with some companies wearing both hats. The above market map outlines a non-exhaustive list of the key enterprise users in the market. It provides the underlying basis and understanding of the market segmentation laid out in this article.

Let’s start things off with the automotive sector. Enterprise users like Toyota, Ford, and BMW use twins to improve business efficiency. The BMW Group operates digital twins to create fully digital one-to-one simulations of its factories and production sites. Twins’ operation enables improved optimization and efficiency due to real-time data analysis.

All of BMW’s sites have been scanned using 3D visualization technology, allowing BMW to introduce new car models into these existing production chains virtually before actual implementation, enabling the car giant to preempt potential production issues before they occur, consequently saving them time and money. An example of this is the BMW iX1. The BMW Group utilizes NVIDIA’s Omniverse software platform to develop these twins, and the company uses the technology for many different purposes.

Similarly, another enterprise user in the automotive space, such as Ford, uses digital twin software developed by engineering company Ansys to create digital twins. An example is the company’s use of twins to build predictive headlights that use real-time data to enhance light visibility when driving.

These headlights utilize virtual environments to direct light when a car moves, indicating light direction using location data provided in real-time by the twin, reducing costs and improving the safety of drivers. BMW Group and Ford are just two examples of automotive companies using digital twins in their production cycles; the market map outlines several others (non-exhaustively) that are doing the same.

In aviation, many parties are currently using digital twins. Aviation giant Boeing uses twins to create virtual replicas of its aircraft by tail number at an exact one-to-one scale, enabling the business to optimize its production process through real-time data inputs that improve maintenance and production speed in line with customer needs and expectations. Thus, using digital twins allows Boeing to reduce costs while building faster and more efficiently.

KLM is another aviation company that uses digital twins to improve its operations. Royal Dutch Airlines (KLM) has partnered with digital twin giant Matterport to map over one hundred digital twins of its fleet, allowing the company to train its workforce more efficiently through a virtual simulation of aircraft that can be accessed through mobile devices and at-home computers.

These twins enable real-time detection of operation errors on aircraft, reducing costs and maintenance time (decreasing cleaning time by 30%) and saving KLM considerable costs while improving the company’s carbon footprint. Likewise, the endeavor gives customers greater utility over their travel, allowing them to understand the plane’s layout and luxuries when picking seats.

Construction is another segment of the enterprise user market that makes up the digital twin landscape. Balfour Betty has dabbled in creating digital twins, working with extended reality provider Holosphere to build a virtual planning room where clients can view entire construction sites virtually. Holosphere employed drone and LIDAR technology to map and accurately recreate construction sites in Unreal Engine 4.

Furthermore, AECOM is also on the digital twin bandwagon, creating a suite of digital twin products for construction processes and customers. Through its DigitalAECOM brand, the construction company has built digital twin models ranging from in-depth, sophisticated simulations to less complex digital twins. Across the company’s many projects, digital twins provide real-time data, cost management, and efficiency-improving measures to reduce operational downtime while improving sustainability to reduce carbon output.

Similarly, cloud computing and consultancy providers offer software solutions for developing twins while using them in-house. An example is Amazon, which created its proprietary software for developing digital twins, the digital twin IoT Twinmaker. The Twinmaker utilizes real-time data and 3D modeling to build digital twins that improve operation efficiency.

Examples of customers include Invista and John Holland. Amazon also employs twins internally, using the technology in their marketing. The conglomerate has been using digital twins to build digital profiles of its customers through its Digital Twin algorithm, with user data input (such as buying a product) feeding it, giving the company the data it needs to market more effectively to consumers.

Companies such as AVEVA wear multiple hats on the consulting side. They act as core software providers for customers by building tailor-made digital twins while acting as a consultancy/advisory firm for clients wanting to learn more about the market through the business’s CONNECT platform. CONNECT links companies with leading digital twin providers, acting as a middle ground for facilitating partnerships and developing digital twins.

The energy sector is another major user of digital twin technology. Shell is leading the way in this regard, having used the technology since 2017. Currently, Shell uses digital twins within its factories to track energy output. An example is its Nyhamna gas plant in Norway, which uses twins to track energy usage using real-time data. The data feedback enables Shell to optimize energy outputs closer to operating limits, reducing outputs, which is a critical use case in older factories that may have unsustainable energy outcomes.

BP is another energy provider that has fully onboarded digital twins. Harnessing what BP calls its ‘APEX System,’ the company has begun to map virtually all its production cycles. BP uses APEX in production systems in the United Kingdom’s North Sea and other select regions globally. Harnessing the technology, BP has seen significant efficiency improvements, with the software delivering thirty thousand additional barrels of energy and gas across the BP production portfolio.

Moving forward, digital twins will play a major role in the further digitization of healthcare, with the industry starting to utilize twins due to their numerous operational benefits. As outlined on our market map, GE Healthcare is using the technology to improve healthcare outcomes. Specifically, in collaboration with GE Global Research Center, the company has built a digital twin called the ‘Hospital of the Future Simulation Suite,’ otherwise known as ‘HoF.’

HoF is a bespoke proprietary software that is designed for healthcare scenarios. The twin can monitor and optimize hospital schedules in and out of surgery, manage the supply and demand of bed lists, and even build effective strategies for developing healthcare organizations. The twin enables healthcare providers to improve operational efficiency, saving expenses and time.

Logistics, retail, and the general technology industry are all immense sectors in their own right, and numerous enterprise users use digital twin technology in their functional processes. On the logistics side, digital twins are important tools for supply chain oversight, with DHL seeing them as an effective supply chain crisis management tool. Digital twins can be effective tools for virtually predicting issues in a chain, simulating these scenarios, which would otherwise be counterintuitive in the real world. Technology companies such as Siemens work with retail leaders like Nestle to develop digital twins to track real-time factory performance.

Similarly, Nestle also utilizes Siemens Tecnomatix Plant Simulation digital twin to simulate various production scenarios. In turn, the partnership helped Nestle reduce waste output while increasing production efficiency.

This article has provided a non-exhaustive breakdown of the digital twin enterprise user market. For more information on the enterprise users in this article, check out our intelligence platform for the latest data and insights.

If you found this article to be informative, you can explore more current Digital Twin news here exclusives, interviews, and podcasts.