In this fast-evolving technology of today, digital twins are finding their place in most industrial sectors. But why on earth is this cutting-edge technology — on the whole — crafted for business needs rather than target consumers directly? The answer lies in the unique needs and applications of digital twins when applied in the areas of manufacturing, production and operation. A Deloitte and Manufacturing Leadership Council recent study presents the enormous potential digital twin technology has across domains, and produces five key findings that underscore technology’s criticality to business:

- Most manufacturers are optimistic about the potential of digital twins and confident in their adoption within the manufacturing industry over the next five years.

- On average, manufacturers are currently piloting or using more than six digital twin use cases across production, supply chain, talent, and customer ecosystems, already realizing benefits in costs, revenue, operational efficiencies, and talent management.

- Executives expect a 12 to 14% increase in throughput and plan to invest significantly in digital twin initiatives.

- Cyber security and data protection are major concerns, as digital twins provide a comprehensive view of plants and factories, necessitating robust measures to safeguard intellectual property and sensitive information.

- A cohort of “pace setters” — companies already pioneering digital twin adoption — exists, setting leading practices and strategies for others to follow.

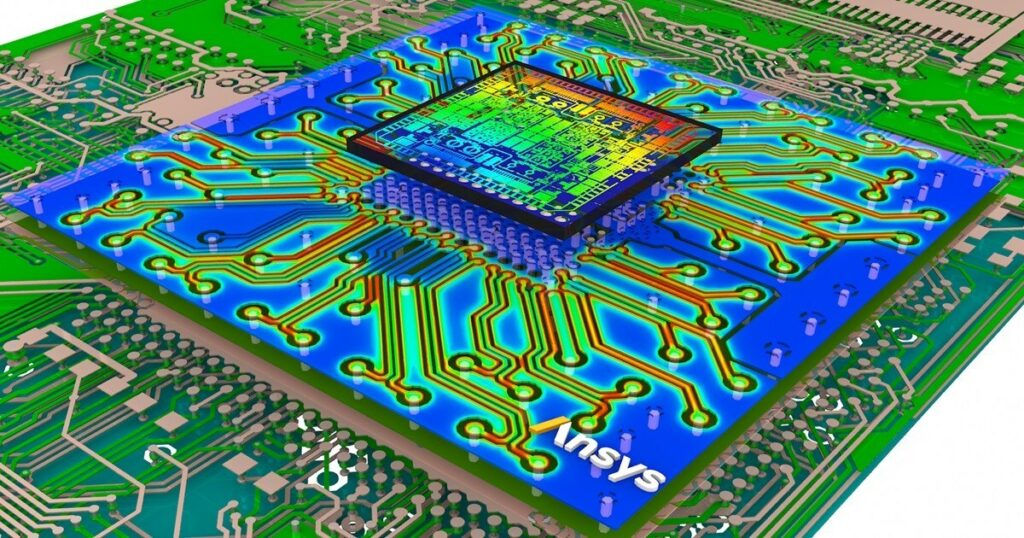

The rationale behind the industrial orientation of digital twins can be understood only when we review the technology landscape prevailing in manufacturing. Data analytics, cloud computing and the Internet of Things have already become precursors of digital twin integration, with most sectors now established on a wide basis. The use of 3D modeling, 3D scanning, 5G, AI, and edge computing, among others, brings the following together in support of the creation of a virtual replica or simulation of the real world.

What is this extended reality, and how will it hold the capacity to change the manufacturing industry?

Extended reality is the overarching general term for AR and VR environments. This means the capability of presenting 3D worlds and objects within the physical environment, a feature that is key to the manufacturing, automotive and real estate industries. XR technologies within manufacturing have immense and transformative potential. Process simulation, real-time monitoring, virtual prototyping, factory simulation, quality control, and virtual maintenance are just a few examples of how digital twins can revolutionize production processes. By creating virtual replicas of facilities and systems, manufacturers can optimize operations, reduce costs, increase throughput, and enhance supply chain performance.

Most modern nations with advanced manufacturing bases offer ample scope for deploying digital twin technology. Global leaders are already using extended reality for immersive training, virtual tours, production optimization, product development, and warehouse management. Deploying these applications in Indian facilities could be game changers for the manufacturing sector.

The benefits are clear, but the road to pervasive digital twin adoption is not without challenges. Companies must juggle concerns as diverse as implementation costs, talent acquisition, integration with existing systems, cybersecurity risks, data protection, and intellectual property safeguards. Overcoming such challenges will be critical for successful digital twin deployment.

Nevertheless, despite these hurdles, the industrial sector is embracing digital twins at a fast pace. The study found 30% of companies are considered “pace setters,” actively experimenting and deploying digital twin use cases. These pace setters are building external partnerships, assigning substantial budgets, and setting up dedicated teams and roadmaps to drive digital twin initiatives.

As industries pursue even more competitive edges, digital twins begin to portray themselves as powerful enablers for process optimization, higher efficiencies, and greater levels of innovation. Consumer-facing applications can develop over time, but for the specific requirements and complexities of industrial operations, the focus is on current needs. Manufacturers will then unlock the full potential of digital twins, opening up new dimensions of productivity, sustainability, and operational excellence, firmly establishing their place at the forefront of the digital revolution.

If you found this article to be informative, you can explore more current Digital Twin news here exclusives, interviews, and podcasts.

Featured image: Credit: Deloitte