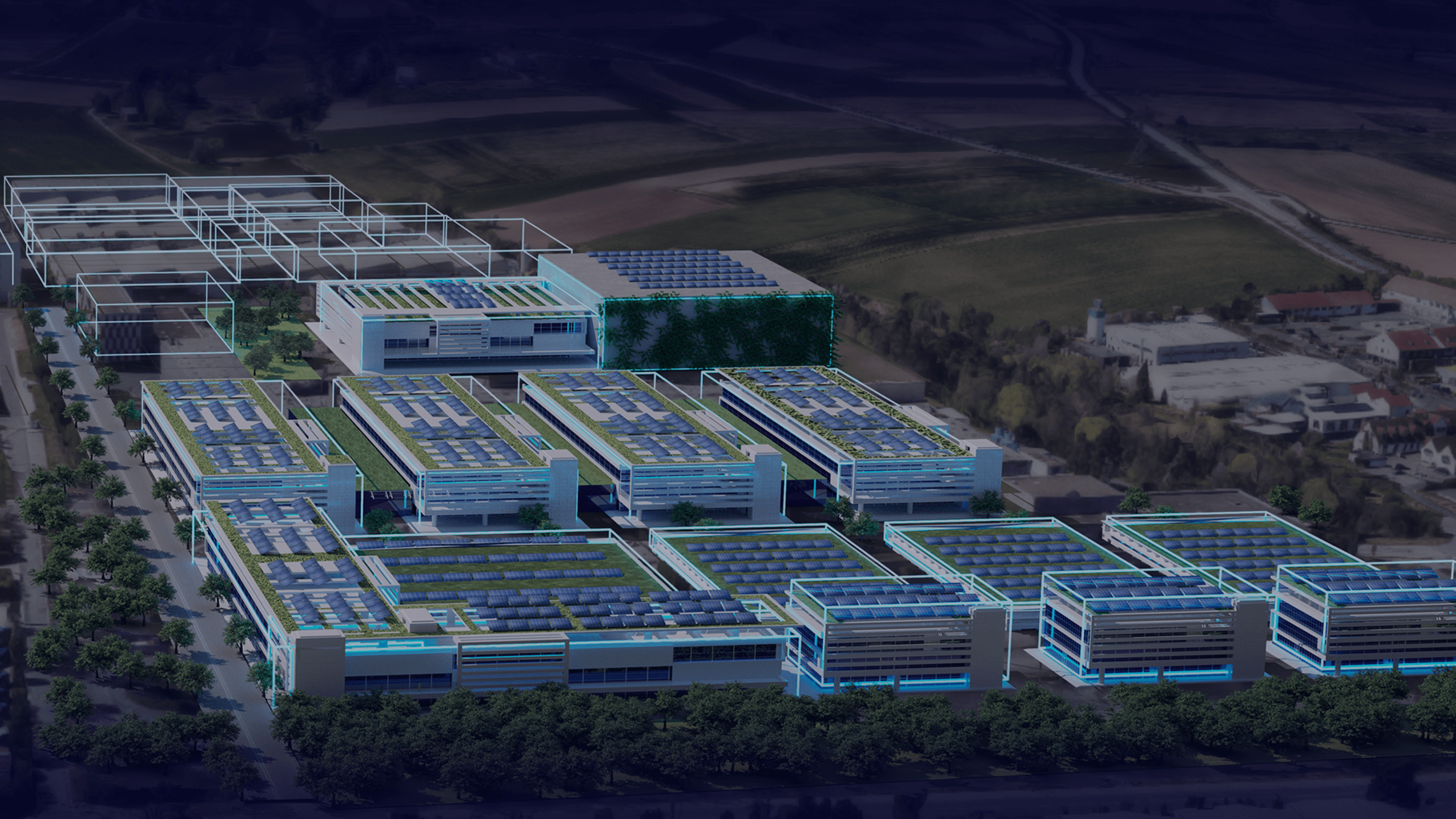

Credit: Siemens

Siemens’ Electronics Factory in Erlangen, Germany, is well known across the industry as a stalwart of digital transformation, using emerging technologies, such as digital twins and artificial intelligence, to boost production outcomes sustainability. Helmed as a sustainable digital enterprise that has mastered full digital transformation, the Erlangen factory has been at the forefront of digital twin innovation.

Siemens has announced several key statistics behind the factory via its landing page. According to Siemens, the factory has performed the following:

- Time to Market reduced by 40%

- Carbon Footprint reduced by 50%

- Quality boost by 60%

- 50% increase in production output

- 50% less energy used per product

- Material circulation reduced by 40%

Similarly, the factory has reported a 50% decrease in carbon emissions and a 25% reduction in energy consumption. These numbers are impressive, with the factory showcasing the potential of emerging technologies, such as digital twins, to shape industrial processes. It also gives a perfect example of how digital twins, alongside other technologies, can work together to boost production while increasing sustainability efforts.

Thus, the Erlangen factory showcases the prospect of these technologies to reduce emissions in the fight against climate change, something companies, governments, and stakeholders should adopt to boost sustainability. In short, Siemens’ Electronics Factory in Erlangen is a prime example of achieving sustainability without sacrificing profits, something others should note.

If you found this article to be informative, you can explore more current Digital Twin news here exclusives, interviews, and podcasts.