With the earliest use cases of the industrial metaverse on the horizon, the technology will help companies create new value and opportunities in dynamic economic conditions, says Rob McGreevy, Chief Product Officer, AVEVA

Curiouser and curiouser, Alice said – and no doubt felt on several occasions – during her extended adventures in Wonderland. Many of us have felt that way recently as the physical and virtual worlds began to blur together in previously unimaginable ways.

This year, the feeling of living in a fantastical world will only accelerate. That’s because 2024 will likely be marked by radical developments around the metaverse. As more applications are built around this innovative iteration of the internet, businesses will come closer than ever to a truly hybrid reality environment.

The feeling of having stepped through the proverbial looking glass will continue to be experienced in online gaming, retail, digital finance, and social media. But industrial business could emerge as the first major adopter, accessing game-changing benefits in the form of a shared, immersive environment and proliferation of data.

2024 will be the year the industrial metaverse truly takes off as multiple companies attempt to assert their position as leaders in the space, offering platforms and technologies to unlock its benefits.

An always-on counterpart to the real world

There have been a few attempts to define the metaverse from a consumer technology standpoint. As we see it at AVEVA, businesses will experience the industrial metaverse as a persistent virtual environment allowing live collaboration across teams, agnostic of interface device, open to the full gamut of data sources and delivering role-based access to real-time operations, data streams and up-to-date engineering data.

In simpler terms, that’s an always-on world that serves as the backbone of the internet, connecting real factories, machines, data and people in palpable ways.

Thanks to the cloud, you’ll be able to log on from any device, anywhere, at any time, to check in on business data and automated systems – and interact with colleagues in other parts of the world in real time. Plug in the power of artificial intelligence (AI), and you can consult historical data, trial new concepts and forecast potential business outcomes. You can do all this on your own – but it’s much more fun with everyone else on board.

Digital leaders are readying to build the industrial metaverse

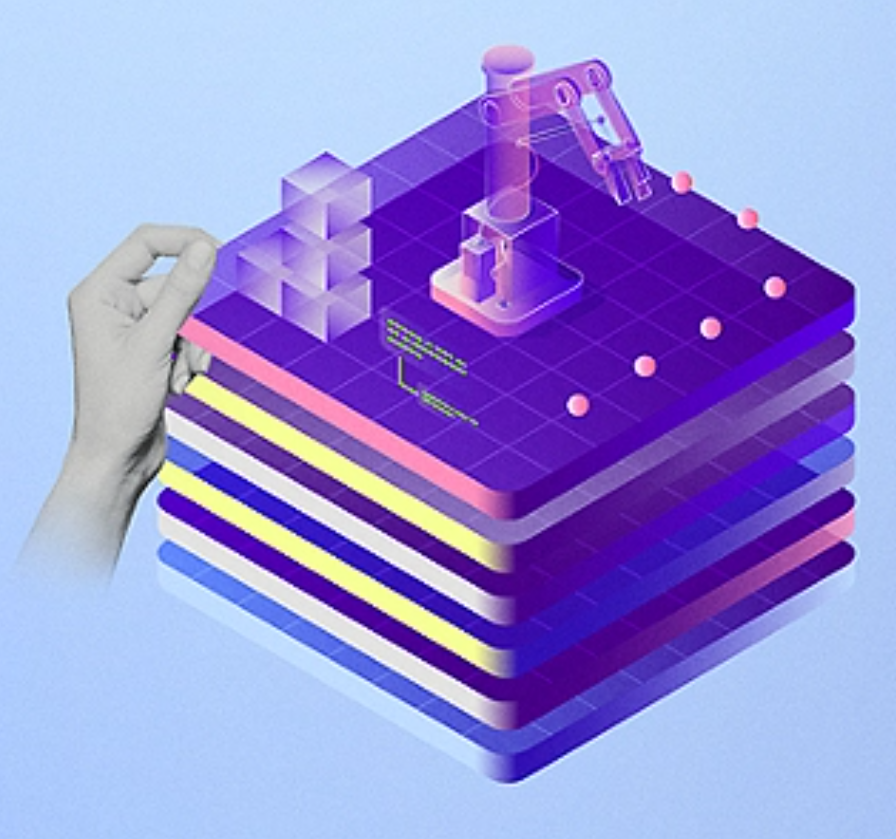

The industrial metaverse brings together three elements: the data (AI-Infused and first principles-enhanced), the digital twin (from birth through extended life), and the experience (seamlessly traversing desktops, mobile devices and wearables via 5G and Wi-Fi).

These building-block technologies are already widely used in industry.

- Companies such as Starbucks Coffee already use an integrated HMI and SCADA platform to view production and inventory data from the shopfloor to the top floor, which in turn supports holistic decisions.

- Digital twins – virtual replicas of physical assets or facilities – have improved operational efficiency through collaboration in the cloud and slashed time to market by over 50% for Norway’s Aker Carbon Capture.

- The North Carolina-based electric and natural gas company Duke Energy has leveraged AI solutions to save millions of dollars through reduced failures, including a saving of $34 million from a single early catch event.

Industrial metaverse applications offer a way to ramp up those results.

By layering collaboration tools onto a digital twin, trusted data comes to life and can be accessed by geographically scattered teams. They can then interact with this information in a shared environment, debating, discussing and taking decisions much more naturally than currently possible.

Industrial benefits from metaverse applications

The industrial metaverse will provide immersive access to expertise from across your business and supply chain within a virtual space. The results will be tectonic shifts in work, training and education with transformative impacts on business value and sustainability.

- Industrial benefits could extend to improved efficiency and productivity. Loading engineering diagrams into a 3D environment facilitates internal collaboration between design teams – and even customers – to support co-innovation.

- Similarly, running a simulation of a new product line can improve design and build to enhance safety outcomes, optimize resource use, promote greater automation and improve margins.

- On the training front, instructional material can be overlaid onto real-world environments, enabling staff to keep up with innovations while reducing reskill time.

- Sustainability gains from the industrial metaverse could come from reduced CO2 emissions. Such gains won’t just result from fewer business travel miles, but with increasing regulatory and customer pressure around net-zero outcomes, industrial enterprises will also be able to leverage industrial metaverse applications to pinpoint low-carbon operational pathways.

Competitive advantage for digital-forward enterprises

Digital solutions have emerged as the biggest value play for industrial enterprises. With resilience and sustainability likely to be critical business demands in 2024 and beyond, industrial companies will need to tap innovative propositions such as the industrial metaverse to prime themselves for a future driven by intelligent data and smart decision making.

Metaverse experiences will slowly be introduced into our daily working life as add-ons to existing software. The earliest use cases for the industrial metaverse are likely to emerge in the form of desktop applications at the edge.

Along the way, companies will need to consider data privacy and security issues, perhaps by tweaking existing digital twin governance. However, while any single organization will be able to create their own industrial metaverse, the first movers will be those that have a strong and committed digitalization strategy.

As with the pandemic, businesses that already have digital services at the core of their operations will have a natural competitive advantage in creating new value and opportunity even in the dynamic economic conditions ahead – and in a way that helps preserve Earth’s natural resources. As Alice might have said, it’s one of the few things that makes sense.

This article was written by Rob McGreevy, Chief Product Officer, AVEVA

See also: What is Metaverse? Guide into the Future of Digital Reality